6800 SERIES

Universal Testing Systems for Tensile, Compression, and Flexure Testing

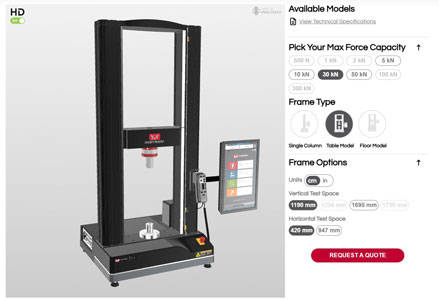

The 6800 Series universal testing systems deliver unparalleled performance across a wide force range — from 500 N to 300 kN — setting the standard for materials testing. Engineered for exceptional accuracy and reliability, these systems are built to exceed the demands of even the most rigorous testing environments. With data acquisition rates up to 5 kHz and ±0.5% accuracy down to 1/1000th of the load cell capacity, the 6800 Series offers unrivaled measurement precision. Whether you're testing delicate specimens or high-strength materials, this platform provides the ultimate flexibility and control to meet any challenge.

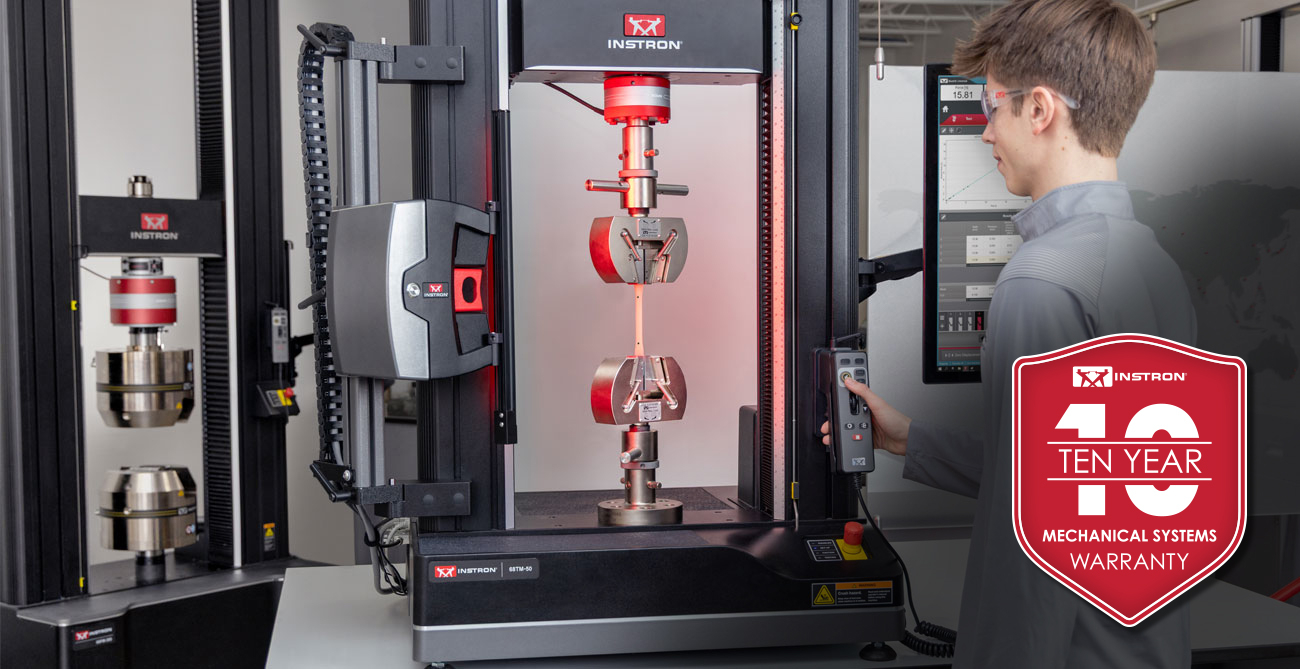

Every purchase of a new 6800 Series system now includes a 10-Year Mechanical Systems Warranty — the first of its kind in the materials testing industry.

NEW 100 kN POWERHOUSE

Compact, Powerful, and Ready to Deliver Exceptional Performance

Instron is excited to introduce the all-new 100 kN table model to the 6800 Series testing systems — delivering the highest force capacity we’ve ever offered in a tabletop frame. At 40% smaller than a standard 100 kN floor model system and compatible with nearly all of Instron’s 100 kN accessories for testing high-strength alloys and composites, this new frame is one of the most versatile and capable universal testing machines we’ve ever developed.

Key Features

- 40% smaller than a standard floor model

- Available in standard and extra-height options

- Operates off a standard power outlet

- Compatible with nearly every accessory up to 100 kN

- Capable of meeting Nadcap alignment requirements

AVAILABLE MODELS

0.02 N (2 gf) - 300 kN Force Capacities

See All Frame Size and Force Capacity Options

Any Application

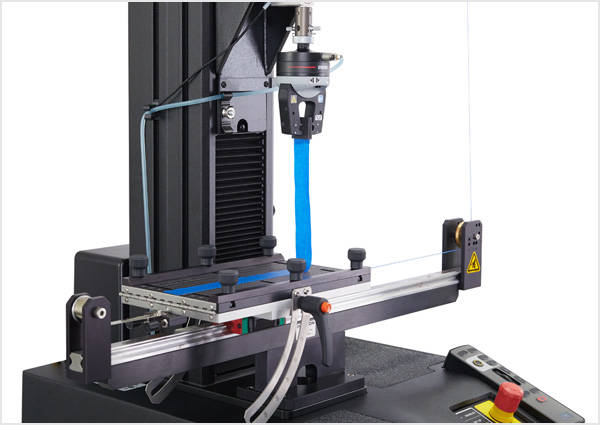

The 6800 series Universal Testing Machines are designed to perform tensile, compression, flex, peel, puncture, friction, shear tests, and more. The systems are compatible with hundreds of grips and fixtures found in Instron’s expansive accessories catalog, with specific configurations designed to perform the most popular tests specific to the biomedical, automotive, consumer electronics, and raw materials industries.

SIMPLER

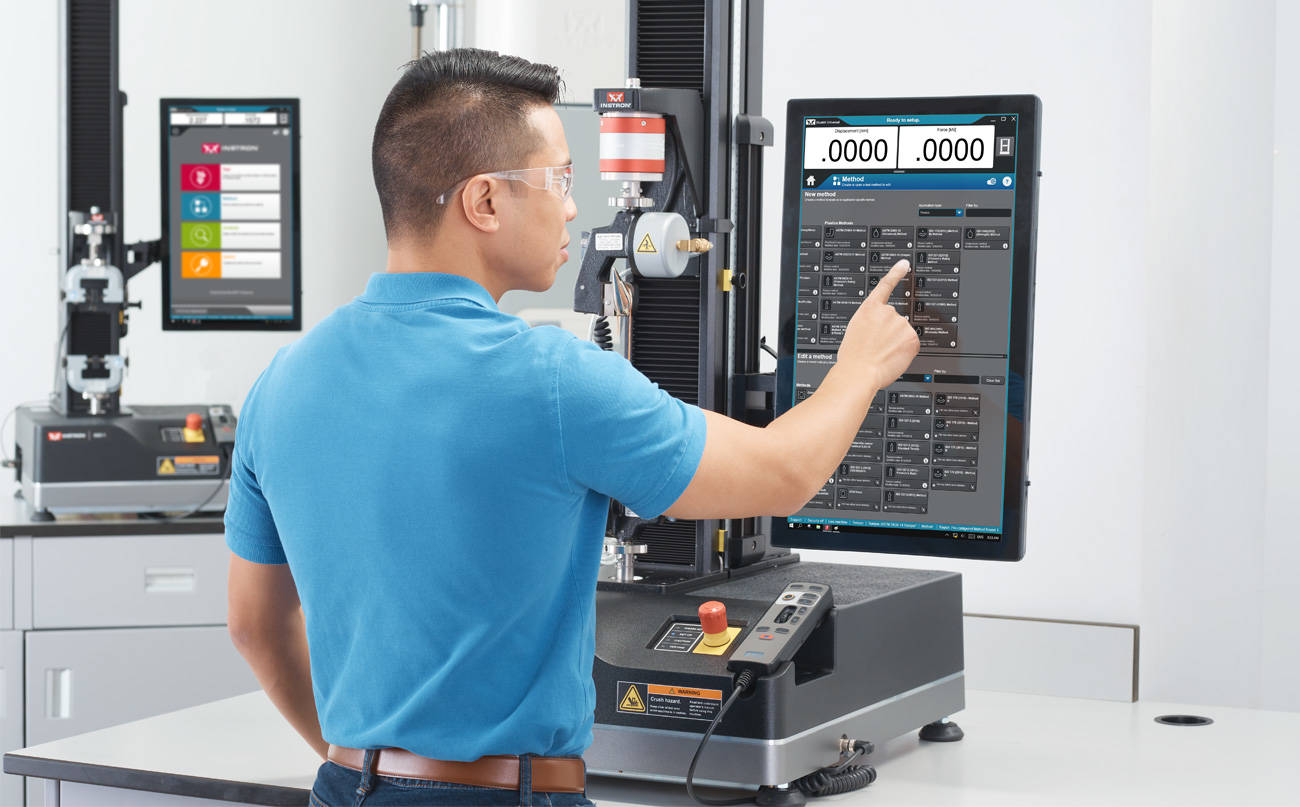

Powered by Bluehill® Universal

The 6800 Series universal testing systems are powered by Instron’s Bluehill Universal software. Equipped with easy-to-understand icons and workflows, Bluehill Universal makes it simple to train users and set up tests, helping you maximize lab efficiency while minimizing costly errors.

QuickTest

For when you need results fast, QuickTest allows users to enter a few simple parameters and run their test within seconds.

Pre-Loaded Templates

Bluehill Universal includes an extensive library of pre-configured methods for some of the most commonly used ASTM, ISO, and EN standards. The methods are packaged in modules that are specific to your testing application.

Workflow

Users can be guided through the entire testing process with step-by-step instructions, ensuring that their tests remain repeatable, simple, and error-free. The prompts can be easily customized with your own text and images.

Auto Positioning

Auto Positioning saves the correct fixture separation or starting location for each test method. This ensures all operators run each test exactly the same way across all shifts every day.

TestProfiler

Build simple cyclic tests that include ramps, holds, and triangle waves. Conditional logic allows users to create looping patterns that help mimic real life scenarios within tests.

Smarter

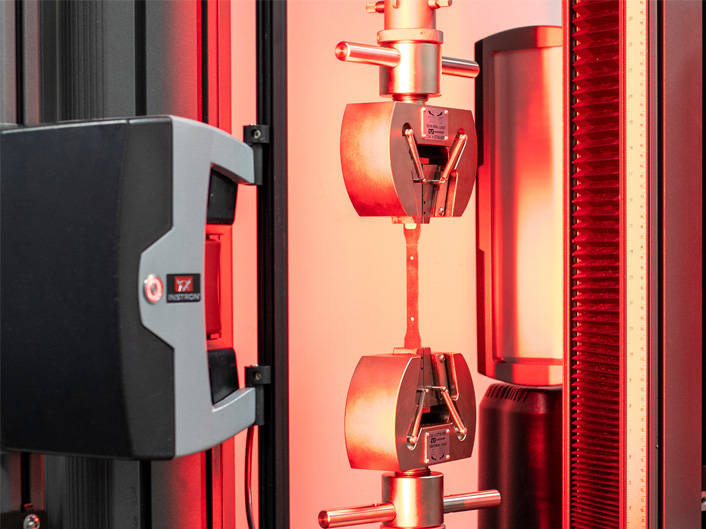

Advanced Performance and Applications

The 6800 Series can be expanded to include Digital Input/Output Channels and up to 11 Sensor Conditioning Modules to ensure compatibility with advanced accessories and external devices. When testing on a 6800 Series frame you can capture synchronized data at a rate of up to 5 kHz with adjustable bandwidth to never miss a test event.

SAFER

Operator Protect

The 6800 Series is built on Instron’s patented Operator Protect architecture. An intelligent workflow keeps equipment and operators safer by controlling system status from setup to test completion.

Built-In Safety Coaching

The 6800 series provides clear visual feedback regarding system status at all times. Users will easily understand when the system is in a safe set up mode, and clearly reminded to exit the test space once these safety limits are removed.

Smart-Close

Air Kit

Finger pinch hazards from pneumatic grips are reduced through lower grip-closing pressure and restricted speed during the set up phase of your test.

ALL-NEW HANDSET

The 6800 handset brings system controls closer than ever before with an all-new ergonomic handset, mounted directly to the frame. Operators can use the handset in the mounted position or removed from its dock.

With 2 user-defined ‘Soft Key’ buttons, the operator can initiate a variety of commands. The Soft Keys can be defined per method, allowing for customization for each test.

With Instron’s patent-pending system architecture, the machine’s movement is restricted to prevent unintended motion of the crosshead.

During set up mode, your system will default to a safe speed appropriate for an operator to work in the test space.

The Fine Position adjustment thumbwheel with tactile feedback allows for precision positioning of the crosshead in 4 μm increments when performing sensitive testing.

Specimen Protect prevents unwanted forces from being applied to the specimen by automatically making fine adjustments to the crosshead, protecting your valuable specimen from damage.

BUILT TO LAST

Every Instron system is built using high-grade materials and expert engineering to meet the highest performance standards. As part of our unwavering commitment to durability and reliability, we proudly offer the industry’s only 10-Year Mechanical Systems Warranty—included at no extra cost with every 6800 Series universal testing system.

Collision

Mitigation

During setup, Collision Mitigation reduces damage to load cells, other equipment, and delicate specimens by stopping the crosshead if force is detected upon return or during a jog.

Load Cell

Overload Protection

During a test, the 6800 Series systems automatically stop when the load cell reaches maximum capacity to prevent damage to the load cell, system, and accessories.

2580 Series

Load Cells

Designed for use with 6800 Series systems, the 2580 Series load cells can measure forces as low as 1/1000th of the force capacity to an accuracy of ±0.5% of reading.

BUILT TO PERFORM

When performing a uniaxial test, accurate stress and strain results can only be achieved with a system that contains robust, precise guidance columns that ensure minimal specimen bending under load.

The 6800 is built for high performance. It features pre-loaded bearings, precision ball screws, an extra thick crosshead and base beam, and low-stretch drive belts to ensure superior performance and longevity.

The 6800 load frames use powerful motors with reserve capacity that allow for quicker rates of acceleration. Maintenance-free brushless AC servomotors enable cyclic, creep, and relaxation testing for up to 10 days (up to 1Hz at 25°C).

Along with a powerful motor, the 6800 drive system consists of a rugged steel casting with a dual-belt drive system. Unlike systems that use gear-reducers, which create backlash and lower drive system stiffness, the dual-belt system provides synchronous movement of the ball screws, eliminating crosshead tilt and aiding system alignment.

NEW FLOOR MODELS

The high force floor model systems have been fortified against shock and vibration which allows for continuous testing at the maximum rated frame capacity.

Reduction in debris ingress has been achieved through gasketing and a patent-pending airflow design. Internal electrical and mechanical hardware is located safely away from directly beneath the test area. The 12 mm metal work surface is treated with an abrasion-resistant coating for durability.

Tall base option on floor model systems provides an ergonomically comfortable testing station, the contoured design allows the operator easy access to the testing space for fixture assembly and a comfortable reach to the new ergonomic handset.

| Model | Force Capacity | Preinstallation Manual The Preinstallation Manual is what you need to know when preparing your facility for a new system installation. It details the site and power requirements, dimensional drawings, lifting and handling instructions, installation procedure, and preventative maintenance details. | Operator's Guide The Operators' Guide provides the information you need to know to start testing after the system has been installed and set up for the first time. The document provides safety information, a detailed introduction, notes on prepping the system, and information on testing specimens. | 3D CAD Models Disclaimer: © 2022 Instron Corporation. These materials can be used solely for the purpose of preparing fixtures for Instron-manufactured equipment. These materials cannot be used, copied, published, distributed, displayed, or reduced to any electronic medium or machine-readable form for any other purpose without the prior express written consent of Instron Corporation. |

|---|---|---|---|---|

| 68SC-05 | 0.5 kN | Download | Download | Find Your Frame |

| 68SC-1 | 1 kN | Download | Download | Find Your Frame |

| 68SC-2 | 2 kN | Download | Download | Find Your Frame |

| 68SC-5 | 5 kN | Download | Download | Find Your Frame |

| 68TM-5 | 5 kN | Download | Download | Find Your Frame |

| 68TM-10 | 10 kN | Download | Download | Find Your Frame |

| 68TM-30 | 30 kN | Download | Download | Find Your Frame |

| 68TM-50 | 50 kN | Download | Download | Find Your Frame |

| 68TM-100 | 100 kN | Coming Soon | Coming Soon | Find Your Frame |

| 68FM-100 | 100 kN | Download | Download | Find Your Frame |

| 68FM-300 | 300 kN | Download | Download | Find Your Frame |